Welcome: Mole Tech is a professional designer and trader in HK for optical field

Over the past 20 years, the costs associated with solar cells, the structures capable of converting light energy into electricity, have been steadily decreasing. The National Renewable Energy Laboratory, a US government lab that studies solar cell technology, estimates contributors to the increasing affordability of solar. They estimate that hard costs, the costs of the physical solar cell hardware, and soft costs, which include labor or costs to obtain required government permits, are about equal (Figure 1). Soft costs have decreased because there are more potential consumers and more installation experts for new solar cells, so companies can produce solar cells in bulk and install them easily. Hard costs are less than half of what they were in the year 2000, mostly due to decreasing material costs and an increased ability of cells to capture light. Engineering more cost-effective and efficient solar cells has required careful consideration of the physics involved in solar capture in addition to innovative design.

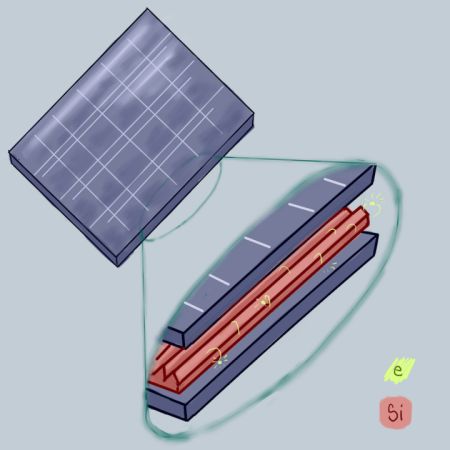

Because solar cells are used to convert light into electricity, they need to be composed of some material that’s good at capturing energy from light. This material can be sandwiched between two metal plates which carry the electricity captured from light energy to where it is needed, like the lights of a home or machines of a factory (Figure 2). Choosing the right material to capture light involves measuring the difference between two energy levels called the valence band and the conduction band. The lower-energy valence band is filled with many small negatively charged particles called electrons, but the higher-energy conduction band is mostly empty. When electrons are hit with particles of light, called photons, they can absorb enough energy to jump from the low-energy conduction band into the high-energy valence band. Once in the valence band, the extra energy in the electron can be harvested as electricity. It’s as if the electrons are sitting at the bottom of a hill (the conduction band) and being hit by a photon that gives them the energy to leap to the top (the valance band).

The amount of energy needed for electrons to jump into the valence band depends on the type of material. Essentially, the size of the metaphorical hill varies based on the properties of a given material. The size of this energy gap matters because it impacts how efficiently solar cells convert light into electricity. Specifically, if photons hit the electrons with less energy than the electron needs to jump from the valence band to the conduction band, none of the light’s energy is captured. Alternatively, If the light has more energy than is needed to overcome that gap, then the electron captures the precise energy it needs and wastes the remainder. Both of these scenarios lead to inefficiencies in solar harvesting, making the choice of solar cell material an important one.

Historically, silicon has been the most popular material for solar cells (Figure 2). One reason for this popularity lies in the size of the gap between silicon’s conduction and valence bands, as the energy of most light particles is very close to the energy needed by silicon’s electrons to jump the energy gap. Theoretically, about 32% of light energy could be converted into electric energy with a silicon solar cell. This may not seem like a lot, but it is significantly more efficient than most other materials. Additionally, silicon is also inexpensive. It is one of the most abundant elements on earth, and the cost of refining it has decreased dramatically since 1980. The solar cell and electronics industries have driven the decrease in purification cost as they have learned better bulk purification techniques to drive the demand of solar cells and consumer electronics.

In addition to decreasing material costs, clever engineering tricks are pushing the efficiency of silicon solar cells closer to their theoretical maximum. In order for photons to be converted into energy, they must first collide with an electron. One trick to increase the likelihood of a photon/electron collision involves patterning the silicon in solar cells in microscopic pyramid shapes. When light is absorbed into a pyramid, it travels further, increasing the probability that the light will collide with the electrons in the silicon before escaping the cell.

In a similar tactic, chemists and material scientists have designed anti-reflective coatings to put on the front of solar cells to prevent useful light from being reflected back into space without ever hitting an electron in the solar cell. Likewise, putting a reflector on the back of the solar cell also allows more light to be harvested. The light that reaches the solar cell and makes it all the way through to the back without hitting an electron gets bounced to the front of the cell, giving the cell another chance of collecting the light.

Contact:

Phone: 19059488638

Tel: 19059488638

Email:

Add: Room 803, Chevalier House, 45-51 Chatham Road South, Tsim Sha Tsui, Kowloon, Hong Kong